Composite rebar is a modern alternative to traditional steel reinforcement used in concrete structures. Made from advanced materials like fiberglass, carbon fiber, or basalt fiber reinforced polymers (FRP).

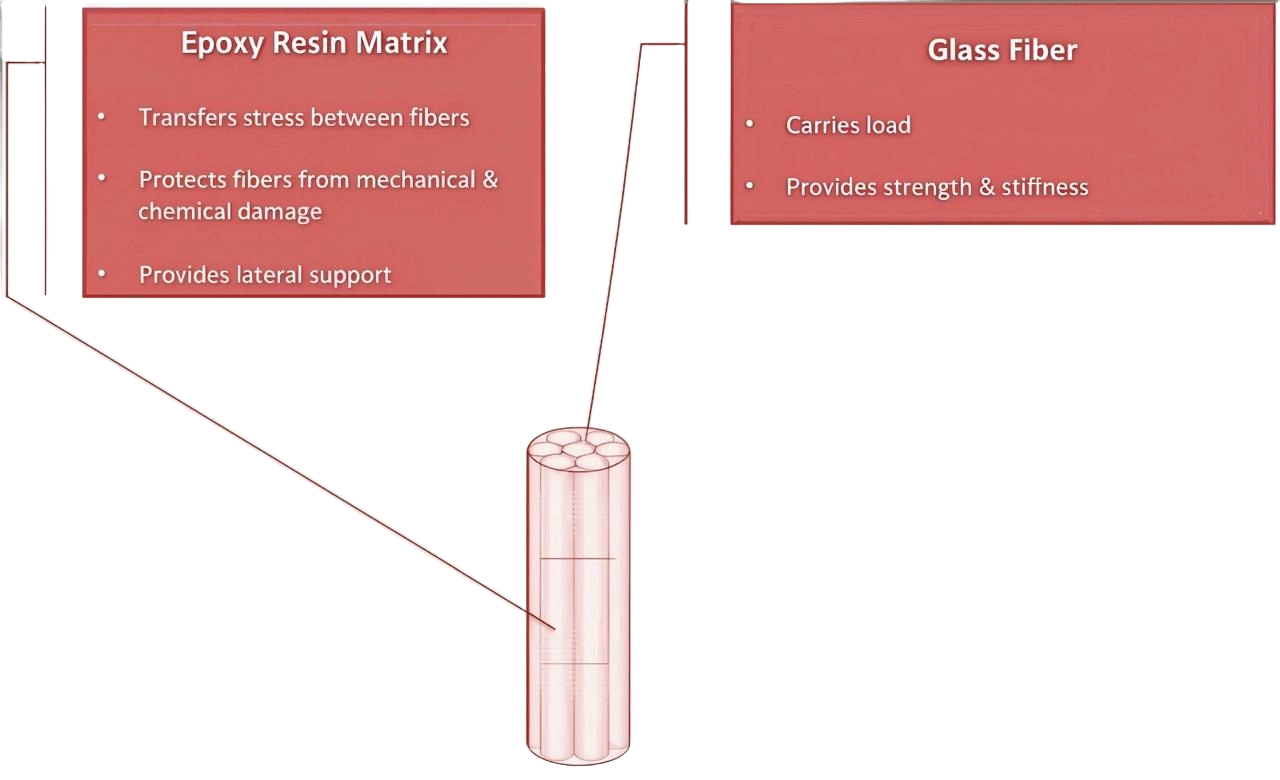

Glass Fiber Reinforced Polymer (GFRP) rebar is an advanced composite material designed as a non-metallic alternative to steel reinforcement in concrete structures. It is composed of high-strength glass fibers embedded in a polymer resin matrix, typically epoxy, vinyl ester, or polyester. This combination provides a unique balance of mechanical, thermal, and chemical properties.

The core reinforcing material, glass fibers, provides tensile strength and stiffness. They are typically arranged in continuous strands for optimal load distribution.

The polymer resin binds the fibers together, ensuring load transfer and protecting the fibers from environmental degradation.

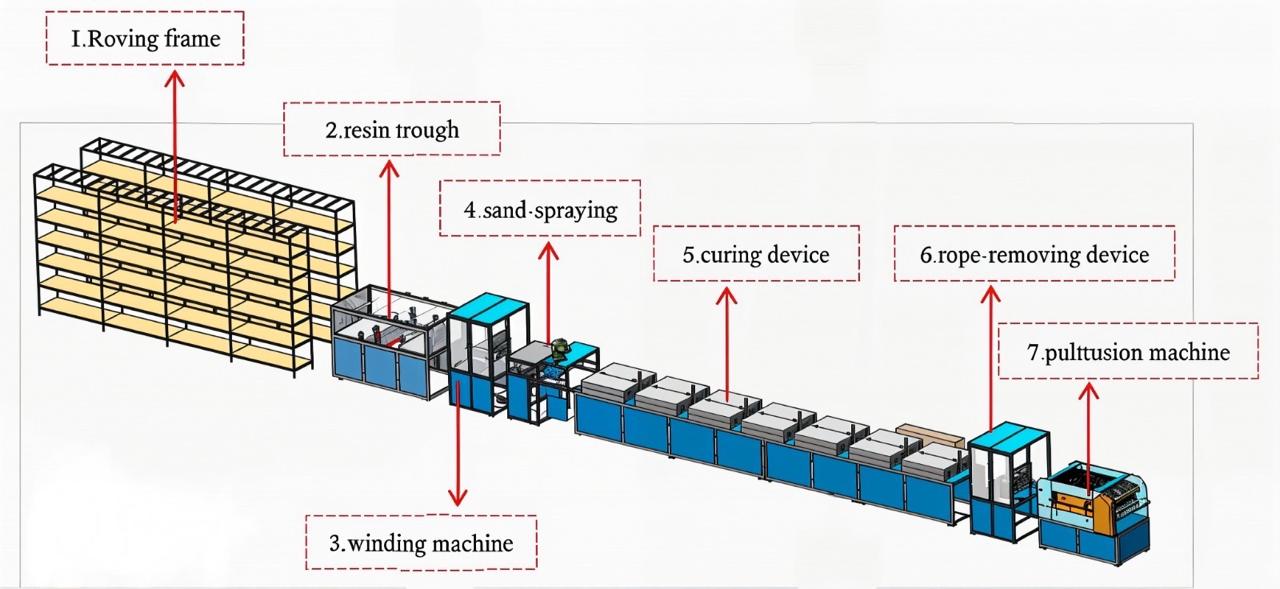

GFRP rebar is produced using a pultrusion process. In this method, continuous glass fibers are saturated with resin and pulled through a heated die to form the desired rebar shape and size. The process ensures uniformity, precision, and high-quality performance.

Dakshin Ultrabar (GFRP), offers distinct advantages over traditional steel rebar, particularly for infrastructure projects in challenging environments. Below is an outline of the primary benefits:

GFRP rebar offers tensile strength 3 times higher than steel.

Inherently resistant to chemicals, acids, and corrosive agents.

Lower manufacturing, maintenance, and transport costs.

Does not conduct heat like steel, preventing thermal bypasses.

Ideal for environments with sensitive electronic equipment.

4 times lighter and 2.5 times stronger than steel for lightweight projects.

Easy to cut using standard tools, fast on-site work, simple installation.

Lightweight nature reduces transportation and shipping costs.

Fiberglass rods last up to 80 years without rust or corrosion.

Resins in polymer matrix distribute impact load, preventing damage.

Retains characteristics in extreme temperatures from -70°C to +200°C.

Durability reduces maintenance, lowering lifecycle costs.

Comfortable for workers, enhancing productivity.

Maintenance-Free: Steel rebar requires periodic maintenance and anti-corrosion treatments to extend its life, often incurring significant costs. In contrast, Dakshin Ultrabar eliminates these maintenance needs due to its corrosion resistance, resulting in zero maintenance costs throughout the structure's life.

In summary, Dakshin Ultrabar provides a durable, cost-effective, and environmentally friendly alternative to traditional steel rebar, making it ideal for projects in harsh, corrosion-prone environments. Its combination of superior mechanical properties, zero maintenance requirements, and sustainable advantages ensures long-term performance and value in transportation and infrastructure construction.

FRP Rebar in Road Projects Circular Value Engineering practice IRC IIT Hyderabad research paper